| Table of Contents |

| 1. Fence trailer 2. Dump trailer 3. Flatbed trailer 4. Lowboy trailer 5. Oil tank trailer 6. Powder tanker 7. Container trailer 8. Side Curtain Semi-Trailer 9. Side Lifter Trailer 10. Drop Side Trailer 11. Conclusion |

| Explore Related Resources |

I’m a seasoned logistics driver with ten years’ experience behind the wheel of lorries, but asking me to pinpoint exactly how many types of semi trailers with pictures exist is quite a conundrum. I do hope an expert in this field might enlighten me. This was the query recently posed to SINOHENG by our Filipino friend Victoria Tuazon.

Below, SINOHENG summarises the ten most common types of semi trailer with pictures, helping you understand the various configurations available and how to select the model best suited to your needs. We provide comprehensive analysis and guidance!

So, let’s get started!

Quick Comparison Table

Before we get started, let’s compare 10 different types of semi trailers with pictures in a table to highlight their key differences—helping you quickly find the right semi trailer for your needs!

| Types | Primary Use | Key Advantages | Customization | Structure | Popularity |

| Fence semi trailer | Transportation of Agricultural Products and Pickled Goods. | Easy loading and unloading, simple structure, and high flexibility. | Yes | continuous beam structure | ✩✩✩✩✩ |

| Dump semi tailer | Particularly suited to bulk cargo handling | Easy loading and unloading, simple structure, and high flexibility. | Yes | Rectangular and U-shaped trailers available | ✩✩✩✩✩ |

| flatbed semi trailer | Suited for transporting oversized and overheight cargo. | No fixed side panels or compartments, enabling loading and unloading from any direction. | Yes | Featuring a low-centre-of-gravity design without side rails. | ✩✩✩✩✩ |

| lowbed semi trailer | The field of transporting large and heavy goods. | suited for transporting large, heavy, and non-disassemblable cargo. | Yes | Low centre of gravity design with a lower main platform surface. | ✩✩✩✩✩ |

| Oil tank trailer | Long-distance transport of liquid, gaseous or powdered cargo. | excellent sealing performance, high carrying capacity, safety and reliability | Yes | Specialised transport vehicles with enclosed tank bodies for cargo. | ✩✩✩✩ |

| Powder tank trailer | Dry granular materials such as cement, flour, and fly ash. | Typically employing a double-cone inclined horizontal tank structure. | Yes | Utilises pneumatic conveying principles for rapid, low-residue unloading. | ✩✩✩✩ |

| Container trailer | 20-foot and 40-foot containers or containerised cargo. | Enhance container loading and unloading efficiency. | Yes | Most feature a frame structure, supporting multimodal transport operations. | ✩✩✩✩✩ |

| Side Curtain Trailer | Commercial vehicles designed for multi-scenario transport adaptation. | A wider range of applications, enhanced vehicle safety and cargo security. | Yes | Featuring front and rear walls, side curtains and a roof canopy. | ✩✩✩✩ |

| Side Lifter Trailer | Enable rapid and flexible loading and unloading of containers. | Capable of rapid, flexible container loading and unloading independently without reliance on other equipment. | Yes | Through a special hydraulic system, the container can be tilted to a certain angle, enabling rapid unloading by utilising its own weight. | ✩✩✩✩ |

| Drop Side Trailer | Steel, building materials, equipment, bagged goods,and other irregular or oversized cargo | Superior performance in loading and unloading speed, cargo compatibility, and operational convenience. | Yes | Semi-trailer equipped with removable or flip-up side panels. | ✩✩✩✩ |

Fence Semi Trailer

Fence semi-trailers are the most common and versatile type of semi trailer, and also our best-selling model. Their key features include easy loading and unloading, simple structure, and high flexibility. The cargo box roof is removable, allowing for adjustable cargo space. They support operations with forklifts and other equipment, helping customers reduce investment costs and generate greater profit value.

Primary Uses:

- Transporting agricultural products, such as fresh produce including fruit and vegetables.

- Suitable for transporting light, bulky goods like cotton and foam boxes.

- Bulk cargo.

- Construction materials such as sand and cement.

- Poultry.

- Electrical engineering, telecommunications equipment, and small-scale construction machinery.

- Garments, electrical appliances, and similar goods.

- Coal, steel, and other bulk materials.

Optional configurations:

- Choice of 3-axle/4-axle/5-axle setups, with customisable load capacity.

- Multiple tractor units available, including flatbed and low-loader variants.

- Side pillars partially or fully removable with adjustable height.

- Multiple door configurations available: long-lock-bar double doors, short-lock-bar double doors, left/right opening, top/bottom opening, double-deck pallet boards, single-deck pallet boards – accommodating diverse loading/unloading and transport requirements.

Product Advantages:

- Features a continuous beam structure for high structural strength, effortlessly handling long-distance transport of heavy cargo.

- Offers multiple configuration options for flexible operation, facilitating the transport of diverse cargo types.

- Equipped with high-level safety features, ensuring robustness and durability.

- Supports deep customisation to meet varied requirements.

TOP10 different types of semi trailers with pictures:Fence trailer.

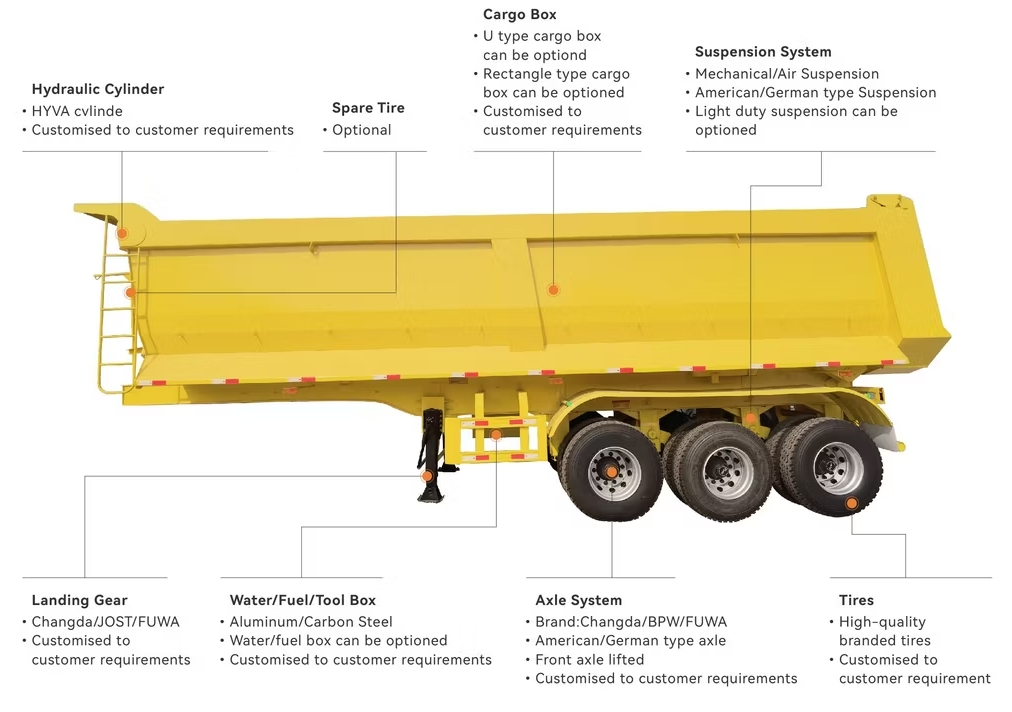

Dump semi trailer

Dump trailers are extensively employed in the transportation of minerals, coal, sand and gravel, construction waste, port operations, and logistics. Particularly suited to bulk cargo handling, they incorporate hydraulic systems enabling automatic tilting to discharge loads. This significantly reduces labour costs while markedly enhancing unloading efficiency.

Primary Applications:

- Road haulage of bulk commodities including coal, sand, gravel, soil, and ore.

- Port bulk cargo transhipment.

- Mining operations and large-scale engineering projects, capable of withstanding harsh working conditions and demanding transport tasks.

- Material transportation within industrial sites such as cement plants.

Product Advantages:

- The body employs newly developed high-strength carbon steel welded construction, featuring a frame composed of longitudinal and transverse beams in an I-beam configuration. This design delivers excellent resistance to bending and torsion. The optimised body structure withstands impact forces during heavy cargo unloading, ensuring rugged durability.

- The U-shaped or rectangular cargo compartment offers a simple structure with superior unloading performance, minimising cargo residue.

- Manufactured from corrosion-resistant steel for extended service life.

- Quantitatively enhanced design utilises high-strength steel and aluminium alloy materials, reducing vehicle weight and boosting transport efficiency.

- Demonstrates outstanding adaptability and reliability, effortlessly navigating complex road conditions and gradients with exceptional power performance.

Optional configurations:

- 3-axis/4-axis/5-axis configurations available. load capacity customisable.

- Multiple tractor units available, including flatbed and low-loader tractors.

- Rectangular and U-shaped trailers available.

- 24m³, 40m³, 42m³ and other body sizes available.

- Rear tipping and side tipping configurations available.

- Fully customisable to individual requirements.

TOP10 different types of semi trailers with pictures:Dump trailer.

Flatbed trailer

Flatbed semi-trailers stand as one of the core tools within the global transport industry. Featuring a low-centre-of-gravity design without side rails, they are particularly suited for transporting oversized and overheight cargo such as engineering machinery, heavy-duty vehicles, rail and mining equipment, construction and industrial materials, and containers. They are truly a universal platform.

Primary Applications:

- Heavy-duty large-scale construction machinery such as excavators, loaders, bulldozers, and cranes.

- Containers.

- Large vehicles including cars, coaches, and tractor units.

- Large prefabricated components, large tanks, and other non-disassembled bulky cargo.

- Steel products.

- Power station equipment, railway carriages, mining machinery, and agricultural machinery.

Product Advantages:

- Platform structure features no fixed side panels or compartments, enabling loading and unloading from any direction.

- Main beams manufactured from high-strength manganese steel, employing advanced techniques such as robotic automated welding and double-layer painting to ensure robust durability, suitable for heavy loads and harsh operating conditions.

- Our flatbed trailers undergo multiple quality inspections, comply with international transport standards, and hold certifications including ISO and CE, guaranteeing each unit’s robustness and reliable performance upon delivery.

- Core components such as axles, suspension, tyres, and braking systems utilise renowned domestic and international brands (e.g., FUWA, BPW, WABCO), significantly enhancing driving stability and braking performance.

Customisation options:

- Body length and platform width.

- Number of axles (3-axle/4-axle/5-axle, etc.).

- Brake system configuration.

- Lighting.

- Electrical interface options.

- Floor type, etc.

TOP10 different types of semi trailers with pictures:Flatbed trailer.

Lowbed trailer

A lowbed semi trailer is a specialised vehicle featuring a significantly reduced chassis height, making it particularly suited for transporting large, heavy, and non-disassemblable cargo. Typically employed for hauling wind turbine components, excavators, construction machinery, and bridge structures, it fulfils the transport requirements of specialised goods. Its configuration, dimensions, and load capacity can be customised to meet specific operational needs.

Primary Applications:

- Construction machinery such as excavators.

- Heavy-duty vehicles.

- Large-scale equipment and infrastructure components including wind turbines.

- Rail vehicles and agricultural/forestry machinery.

- Steel products and oversized cargo.

Product Advantages:

- Low centre of gravity design with a lower main platform surface, reducing the risk of cargo sway and vehicle rollover.

- Gooseneck section typically fabricated from high-strength steel weldments, capable of withstanding sufficient vehicle towing forces.

- The chassis, as the core load-bearing component, is manufactured from high-strength alloy steel, offering exceptional strength and toughness.

- Axles are sourced from premium manufacturers.

- Critical components (such as the main beam) can incorporate special reinforcement designs, including a double-parabolic inner curve configuration to mitigate the risk of main beam fracture.

Customisation options:

- Optional ABS anti-lock braking system for enhanced driving safety.

- Number of axles.

- Load capacity rating.

- Body dimensions and even structural composition.

- Brake system configuration.

- Lighting.

- Electrical interface options.

TOP10 different types of semi trailers with pictures:Lowbed trailer.

Oil Tank Trailer

A oil tank trailer is a commercial trailer specifically designed for the long-distance transport of liquid, gaseous or powdered cargo. It features excellent sealing performance, high carrying capacity, safety and reliability, and strong adaptability to road conditions.

Primary Applications:

- Energy transportation.

- Chemical transportation.

- Infrastructure and industrial materials transportation.

- Food-grade transportation.

Product Advantages:

- Large capacity enables bulk cargo transport in a single journey, reducing transit frequency and costs.

- Superior sealing prevents leakage and evaporation during transit.

- Tank constructed from high-strength carbon steel, offering superior pressure resistance and corrosion resistance.

- Fully equipped with safety accessories, such as safety valves and emergency shut-off devices.

- Supports multi-compartment design, enabling simultaneous transport of multiple fuels to enhance operational efficiency.

Configuration options:

- Axle brand.

- Tank material.

- Number of compartments.

- Body colour.

- Optional flow meters, fuel pump systems and other configurations.

TOP10 different types of semi trailers with pictures:Oil tank trailer.

Powder Tank Trailer

The powder tank semi-trailer, also known as a bulk powder transport semi-trailer, is a specialised vehicle designed for the transportation of dry granular materials such as cement, flour, and fly ash. It is equipped with its own power source for the automatic loading and unloading of cargo.

Typically employing a double-cone inward-tilting horizontal tank structure, equipped with safety systems such as ABS anti-lock braking, and supporting bespoke customisation.

Primary Applications:

- Dry powdered and granular materials with particle diameters not exceeding 0.1mm, such as bulk cement, lime powder, and fly ash.

- Transporting materials with poor flowability, including carbon black, soda ash, PTA, and urea.

- Even lumpy materials such as ores.

Product Advantages:

- Utilises pneumatic conveying principles for rapid, low-residue unloading, achieving residual rates as low as 0.2%.

- Fully enclosed tank design provides effective protection against rain and moisture, ensuring material quality and minimising environmental contamination.

- Capable of transporting substantial volumes of powdered materials in a single journey, significantly enhancing transport efficiency.

- Smooth tank interior walls with optional specialised flow-guidance devices ensure unimpeded material movement during transit, preventing clumping.

- Vehicles equipped with a comprehensive suite of safety devices.

Configuration options:

- Number of axles and brand.

- Tank material.

- Body colour.

- Safety features.

- Other.

TOP10 different types of semi trailers with pictures:Powder tank trailer.

Container Semi-Trailer

A container semi-trailer is a specialised trailer designed for transporting containers or similar cargo. Most feature a frame structure, supporting multimodal transport operations. This significantly enhances container loading and unloading efficiency while reducing cargo damage rates. Annual maintenance costs are over 60% lower than those for box trucks.

Depending on their structural design, container semi-trailers can be further categorised into flat-beam, large gooseneck, and small gooseneck types to accommodate varying requirements for loading flexibility and load-bearing capacity across different operational scenarios.Primarily utilised in logistics systems supporting vessels, ports, shipping routes, highways, transhipment terminals, bridges, tunnels, and multimodal transport.

Primary uses:

- Transporting 20-foot and 40-foot containers.

- Containerised cargo.

- Supporting multimodal transport.

Product Advantages:

- Constructed from high-strength steel for robust and durable structure.

- Modular design + lightweight construction enhances load capacity while reducing weight, improving fuel efficiency.

- Direct container loading onto the chassis, secured via twist-lock mechanisms.

- Gooseneck structure incorporates a 10–30 cm height differential at the front, specifically suited for containers with recessed bases. This reduces overall loading height by 15% and significantly improves transport stability.

Customisation options:

- Safety configuration.

- Number of axles and brand.

- Load factor.

- Body dimensions and even structural composition.

- Brake system configuration.

- Lighting.

- Electrical interface options.

TOP10 different types of semi trailers with pictures:Container semi trailer.

Side Curtain Semi-Trailer

The side curtain semi-trailer is a commercial vehicle engineered for versatile transport applications across multiple scenarios. Its soft-top structure and flexible securing mechanisms ensure cargo security while optimising loading/unloading efficiency and maximising vehicle payload capacity.

Primary Applications:

- Palletised cargo.

- Food and beverage transportation.

- Bulk goods.

- Daily necessities.

- Steel coil transportation.

- Paper roll and carton packaging transportation.

- Transportation of high-volume, lightweight goods such as foam and textiles.

- Intercity short-haul distribution.

Product Advantages:

- Forklift loading and unloading is possible from both sides and the rear. For large, heavy cargo, the sliding roof can be opened to facilitate crane lifting onto the side curtain trailer floor for professional securing.

- Side curtain semi-trailers feature front/rear walls, side curtains and a roof, providing excellent protection for transported goods. Combined with various securing devices within the curtain semi-trailer, cargo can be effectively secured, ensuring both cargo safety and vehicle security.

- Side curtain semi-trailers offer broader application scope with enhanced overall vehicle and cargo safety, making them an ideal replacement for flatbed and box semi-trailers.

Customisation options:

- Safety configuration.

- Number of axles and brand.

- Load factor.

- Body dimensions and even structural composition.

- Brake system configuration.

- Lighting.

- Electrical interface options.

TOP10 different types of semi trailers with pictures:side curtain semi-trailer.

Side Lifter Trailer

A side lifter trailer is a specialised vehicle designed to independently perform container loading and unloading operations at ports, without requiring external cranes from the port or yard. It is an indispensable piece of equipment for port logistics operations.

Primary Applications:

- Port terminals

- Railway freight stations

- Multimodal transport hubs

- Warehousing and transhipment centres

- Logistics sector

Product Advantages:

- Capable of rapid, flexible container loading and unloading independently without reliance on other equipment.

- Enables container stacking.

- Side-lifting operation offers superior manoeuvrability and operational flexibility compared to traditional front-lifting methods in confined spaces.

- Particularly suited for rapid transfer scenarios in port short-haul operations, warehouse transhipment, and multimodal transport, significantly reducing logistics time.

- Equipped with multiple stabilisation devices to prevent hazardous situations such as vehicle rollover during tipping operations.

Optional configurations:

- Premium models equipped with an independent engine-driven hydraulic system.

- Container stacking functionality available upon request.

- Customisation available for additional requirements.

TOP10 different types of semi trailers with pictures:side lifter trailer.

Drop Side Trailer

A drop side trailer is a semi-trailer equipped with removable or tiltable side panels, suitable for the medium-to-long-distance transport of various goods. Compared to traditional box-type or enclosed semi-trailers, it offers superior performance in loading/unloading speed, cargo compatibility, and operational convenience.

Primary Applications:

- Steel products

- Construction materials

- Plant and machinery

- Bagged goods

- Agricultural produce

- Irregular or oversized cargo

Product Advantages:

- Side panels on both sides can be swiftly opened or removed. Whether utilising forklifts for side loading/unloading or manual handling, this facilitates efficient and convenient operations, significantly reducing loading/unloading time.

- Compatible with diverse cargo volumes and types, handling virtually all cargo categories from palletised goods and long-form materials to light equipment and engineering auxiliary materials.

- Featuring a straightforward structure and highly interchangeable components, routine maintenance and part replacement for the tipper semi-trailer are exceptionally straightforward, thereby reducing long-term operational costs.

- Incorporates axles and suspension systems from renowned domestic and international brands (such as FUWA and BPW). Even under full load and on uneven road surfaces, the vehicle maintains stable operation, responsive braking performance, and safe, reliable functionality.

Customisation options:

- Two-axle, three-axle or multi-axle configurations.

- Side panel height.

- Trailer length.

- Suspension system.

- Tyre specifications.

- Braking system.

- Additional customisation options available.

TOP10 different types of semi trailers with pictures:Drop Side Trailer.

Conclusion

The above presents our selection of the top10 different types of semi trailers with pictures in china. Each model serves distinct purposes and caters to varied operational scenarios. We trust this overview has provided you with a foundational understanding. Should you still be unable to identify a suitable semi-trailer for your requirements, simply click the ‘Contact Us‘ button in the bottom right corner to enquire further.

Explore Related Resources

Want to see more products? We can offer you a number of options that could be the best choice:

· Dump Trailer

These are some of the recommended readings. They should come in handy, we think.

· 2 Difference Semi Trailers: Flatbed Trailer and Lowboy Trailer

And yet you have not discovered what you need? Don’t hesitate to contact us. We have 24 hours of assisting you.